What Is The 32 mm Millimeter Cabinet System?

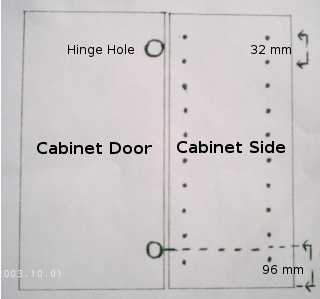

Hinge holes and shelf holes are perfectly aligned using the 32 mm system. The hinge plate fits into the adjustable shelf holes.

What does a 32 (mm) millimeter increment have to do with the way a cabinet is built? It’s referred to as a set system or standard in the cabinetry industry. This is a fabrication method that was founded in Europe thus we get the name European style cabinetry. Almost all of the kitchen, bath, laundry, garage, office and wall-unit hardware components, for this style of cupboards, are made to work with the thirty two millimeter system. Industrial machines, relating to the cabinet manufacturing industry, have been invented and continue to evolve around this metric unit of measurement. Most of the cabinet industry hardware such as hinges, hinge plates, drawer slides and decorative handles are designed to correspond with this metric measuring method. Because of this style of manufacturing, large companies are able to mass produce pre-assembled cabinets and sell them through outlets such as Home Depot or Lowes. Also the RTA (or, “ready to assemble”) cabinets that you purchase in a box, often found in Office Depot, Office Max, Walmart, and other department stores, are manufactured using this thirty two millimeter production method.

How Does The Thirty Two Millimeter Cabinetry System Work?

Below are some examples of how the thirty two millimeter system operates in relation to the machines and cabinetry parts that are manufactured using this precise method. When all of the calculations and settings are accurately determined, in relation to the actual cabinet parts, this method of production eliminates hours of manual labor. It also enables companies to mass produce pre- assembled cabinets and RTA (or, “ready to assemble”) style components in a box.

Adjustable shelf hole drilling (or, “ boring”) machines:

Machines have been manufactured to drill multiple adjustable shelf holes in cabinet sides or ends. These holes are exactly 32 mm apart from one another and the gang drilling machines (refer to photo) can punch out hundreds of holes within a matter of seconds. These machines are usually pneumatic (or, “air powered”) and come in a variety of styles to suit various budgets that cabinet manufactures may have. Some of the drilling machines that cost less are actually manually operated by pulling an arm which causes the gang drill to create the adjustable shelf holes. The Ritter Manufacturing company has a collection of these machines that fit every point of the budgeting scale that a fabrication company may fit into. The costs range from a few thousand dollars to hundreds of thousands of dollars for these adjustable shelf hole boring machines.

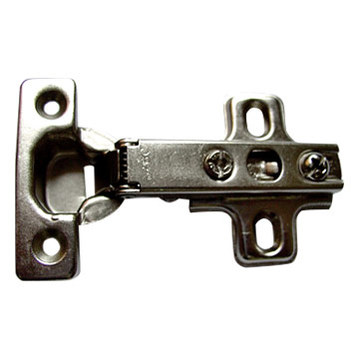

The wing on the right side is the hinge plate. The holes are 32 mm apart. Screws or nylon dowels will hold the hinge plate onto the cabinet side when inserted into the adjustable shelf holes.

Hinge and hinge plate dimensions that correspond with the shelf hole positions:

European style cabinet hinge plates, such as the Grass or Blum brand, are manufactured to match the thirty two millimeter shelf holes. Many of the larger manufacturing companies use what is referred to as a press-in hinge plate. This means that the screws which hold the cabinet hinge plate on the side or end of the cabinet are exactly 32 millimeters apart from one another. Attached to the hinge plate screws are small nylon dowels (refer to the photo at the bottom of the page) that are slightly larger than the 5 millimeter wide hole which the boring machine made for the shelf pins. These plates are pressed into the holes by another machine or knocked on by hand. The positions are precisely calculated by the cabinet manufacturing company to coincide with the doors and hinges that will match the location of the plates. (refer to photo at the top)

Drawer slides that match the system:

The average person would not know this, but the distance between the screws on drawer slide hardware match with the multiplication of 32 mm increments. Three times thirty two is equal to two hundred and eighty eight millimeters. This might be the distance between the screw hole centers on a particular set of cabinetry drawer slides. Manufactures can purchase the slides with nylon dowels pre-assembled on the drawer hardware. Machines are used to press the parts into the pre drilled holes in the cabinet sides. Sometimes they are actually knocked on with rubber mallets rather than pressed into place. High production shops that manufacture mass volumes of cabinetry use machines for many of the the details of the assembly process. Many of the medium sized fabricators have to substitute manual labor in place of owning a machine to attach the drawer slides with; they do this with a large rubber mallet and just knock them into the holes on the cabinetry sides.

Cabinet handles work off of the 32 millimeter increments:

One of the most popular sizes of cabinet handles that we have used with our kitchen designs is refereed to as a 96 millimeter handle. Obviously, this means that the hole centers are this distance apart from one another. Here again, machines will drill two holes in a cabinet door that are exactly 96mm apart from one another to coincide with the screw holes on the handles.

More about 32mm cabinet industry machines:

More about 32mm cabinet industry machines:

One of the great things about using this system is that many of the machines serve several different functions. Here’s what I mean. One machine might be capable of preforming three different tasks for preparing cabinet parts for assembly. As an example, one setting might drill all of the adjustable shelf holes in the cabinetry ends. Then by removing several of the drill bits and changing the location of guide fences and stops, the same machine will drill all of the cabinet doors for the 96mm decorative handles. With another alteration, to the same machine, the manufacture is able to drill all of the holes for the knock on drawer slides. Each function has its own set of metric setting that the cabinet manufacture must develop in order to make all of the parts fit together perfectly.

This European hinge photo shows the nylon dowels that press into the pre-drilled holes.

These are just a few examples of how this 32 (mm) millimeter system works in the cabinet manufacturing industry. Obviously, by now you understand that this system of measurement extends into every area of hardware that can be purchased for fabricating cabinets and adding extras to your kitchen, bath, laundry room, wall-unit or office furniture. What I mean is pull-out trash cans, special cabinet assembly fasteners, wire baskets, locking systems and many other items are manufactured with the thirty two millimeter system in mind. Machines, combined with perfectly calculated measurements, cut the manual labor to a minimum. Especially in comparison to drilling the holes in all these parts by hand and screwing everything on manually.

Hi!

I had cabinets with Grass hinges just like the ones you pictured. One broke, and i found an online company to replace it (I had to send in the old one and they sent the exact replacements). Unfortunately, they didn’t send the nylon dowels, and I can’t find those anywhere!!! Do you know where I can get those, or what I should do if I can’t find them??? Thanks so much!

You can purchase the nylon dowels at a cabinet supply company. If you can locate a large cabinet manufacturing shop in your area, they will have some. You may even find a hinge at Lowes, Home Depot or another hardware store that has the nylon pieces. Unfortunately, you will have to purchase the hinge too. We have a local place called Habitat for Humanity where they have a very large warehouse of items that people donate. I can almost always find a replacement hinge or part that I need there.

It only makes sense to use this system. The machinery and the hardware are all set up for this. I use the Festool LR32 system and using this method saves me a lot of time. Even all our drawer slides have it. Why not eliminate setups?

There is a great book that talks about this. All my drawings are metric but I speak in inches to my customers.

I can’t stand dividing fractions. Milimeters are soooo much easier.