Wood Edge Formica Counter Top

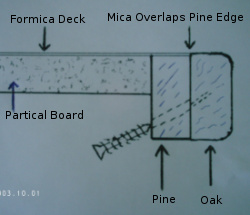

Diagram Attaching Wood Edge To Plastic Laminate Counter

Do you want to enhance your kitchen by adhering a wood edge to a Formica countertop? Will you be attaching it to an existing top or will you be building one? I will be discussing several methods of how to attach a decorative wood edge to your plastic laminate counters. There is really not one set method of how to apply a piece of oak or maple edging to a mica top. I am going to share with you the easiest way to adhere the molding using the most common tools that a person may have in their shop or tool box at home. Primarily, I will be discussing how to build a new plastic laminate counter top that has a real wood edge. At the end of this article you will find two methods that can be used on existing tops that are already installed.

How to Attach Decorative Wood Edge To A Formica Top

How you attach the real wood edging to the plastic laminate counter top will be determined by the type of materials that you’re working with. The method that I am explaining is for using particle board to fabricate your Formica counter with. If you are using plywood, omit applying the pine edge. The main thing is to make sure that there is no way water can damage the top by seeping through the seam where the Formica meets the decorative edge. The way we do this by applying a pine strip for the real wood to adhere to. Attaching this piece will require that the sub top or particle board be cut an additional 3/4” shorter. So if your finished top size is to be twenty five inches deep, you will have to deduct an inch and a half off of that overall dimension. You are deducting 3/4” which allows room to attach the pine edge and another 3/4” to leave room for applying the wood edge. The plastic laminate will not be glued to the counter until after the pine has been adhered to the particle board and before the hardwood molding is applied.

Steps For Attaching a Wood Edge To A Formica Counter Top

Here are the necessary steps that need to be used for attaching the wood edge to a Formica countertop. Remember this, applying yellow glue to the parts will greatly reduce any possibility of ever having water damage occur to the oak or maple wood edges in the seam area. Just make sure to use use the glue sparingly. Refer to the above photo before reading these steps.

1) Cut the particle board, counter deck, one and a half inches shorter than the overall counter top size or depth.

2) Cut strips of pine 3/4” x 1 1/2” x the necessary lengths.

3) Pre-cut the real wood edge pieces oversize by a few inches

4) Build your counters. Do not use any build up pieces on the front edge where you will attach the pine and oak (or, “maple”) pieces for the molding. Refer to step 13 for more details.

5) Apply the pine to the particle board using yellow glue and some type of fasteners, either screws, small nails or staples. Obviously, you will be making miter cuts on the decorative pieces but it is not necessary for the pine. The ends can be left a ninty degree angles.

6) Sand the deck of the counters in preparation to glue the plastic laminate on the top

7) Glue the Formica onto the particle board, route it off and block sand the edges of the mica flush to the pine strip.

8) Use masking tape and stick it perfectly along the edge of the Formica where the decorative molding will be glued on. This will protect against getting glue, stain or the clear coat finish on the laminate.

9) Using a 3/16” bit, drill a pilot hole from underneath the counter through the pine in the direction of where the wood edging will be adhered. (refer to photo)

10) Using bar clamps attach the wood edge to the mica counter. Be sure to use yellow glue and have a damp rag handy so you can wipe the excess off. Don’t use so much glue that it gets all over the masking tape and possibly the finished laminate. By applying one decorative wood edge at a time you can adjust things out as you go. You will need about four to six bar clamps to do this procedure correctly.

11) Once you have the wood edging perfectly flush with the masking tape and bar clamped in place, screw the decorative wood into place using 1 1/4” long screws. It will be necessary to adjust things flush as you go along a little at a time. I’m sure you will be working with wood that is not perfectly straight.

12) Whip the yellow glue off being extra careful to not get “ANY GLUE” on the Formica.

13) Attach any build up pieces to the bottom of the counter that are necessary to make it set level when it is installed. Only add a 1” thick piece where the sink will get installed. This will allow enough room for the plumber to attach the sink clips if you have a stainless steel sink.

Tip: If you screw the pine onto the particle board, when you are routing the plastic laminate off be careful to not let the router-bit guide go into the pilot holes where the screws were used to attach the pine in place.

After Applying the Wood Edge to the Mica Countertop

Once you have successfully completed the process of applying the wood edge it will be necessary for the mica counter to set over night. This allows plenty of drying time for the glue. Do not remove the masking tape but leave it in place. Now comes the process of using the vibrating sander to level the real wood down to the plastic laminate edge. Actually, you will be sanding it to the masking tape. Start with 100 grit paper and finish it off with 220 grit. Once you are satisfied with the results of adhering the wood edge and sanding it flush with the tape on the mica, you can put whatever the finish is that you desire the decorative piece to have on it. When it is time to remove the masking tape, after you have applied the finish to the edge and allowed it to thoroughly dry, take your time and use extra care as you begin to pull the masking tape off. You do not want to chip or pull the clear coat finish off.

If you would like to know other methods of how to apply a wood edge onto a plastic laminate counter here are a few other quick suggestions.

Attaching a wood edge to laminate counter using a Lamello biscuit joiner machine. This is an extremely accurate way of attaching the edging and also a rather fast way as well. The Lamello biscuit joiner is not exactly something that you’re going to use often, unless you are doing a lot of wood working. Years ago, when I worked in a high production shop, we used to adhere all of the oak decorative pieces to the plastic laminate counters using this machine because it is a fast and accurate method.

Applying a wood edge to a Formica counter top using finish nails. If your decorative pieces have a nice router detail that will hide the nail holes, then it’s OK to use this method. I do not recommend that you apply the molding this way if you’re fabricating the laminate top for a customer, unless you explain the process to them and have an understanding in writing. Pre-drill small holes in the hard wood edge and use yellow glue and small finish nails to adhere the piece to the Formica counter. Use a nail set (or, “punch”) to recess the nail head into the wood. Apply a wood filler that is the same color into the holes. If your working on existing tops that are installed, using this method or the Lamello biscuit joiner machine technique, for applying the wood edge to the plastic laminate counter, will be the best choices of the three methods that we have discussed.

How I approach attaching a decorative edge to a Formica top varies depending upon the situation. If I am in the shop, I always attach the real wood using a drill and 1 1/4 inch long screws. I do not have a Lamello machine, so I must use a drill and screws to apply the pieces onto the counter top. I always make sure that I am not rushed through any of the steps for applying the molding to the Formica counter. If you keep this attitude too, you will have a work of art to be proud of once you have finished your kitchen project.